ISO 9001:2015 certified custom manufacturer of prototype die permanent mold aluminum castings. Materials include 319, 333, 354, 355, 356, A356, 357, 360, 380, 535, and 852 aluminum alloys. Capable of producing component parts up to 125 lbs. Casting methods include low pressure, tilt pour, static pour, and semi-permanent mold. Other capabilities include lathe work, powder coating, plating, and vertical and horizontal machining. Serves food and beverage, robotics and machine tools, medical, and gasoline industries.

Description

Name & Description

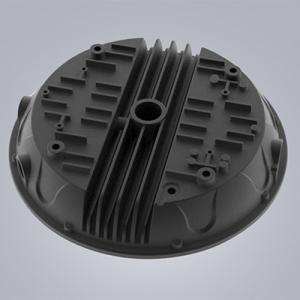

die casting electronic components

Material

casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

electronic parts

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium die casting parts