These are used when the die casting machine spare parts cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace. Then a precise amount of molten metal is transported to the cold-chamber machine where it is fed into an unheated shot chamber . This shot is then driven into the die by a hydraulic or mechanical piston. The biggest disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

escription

Name & Description

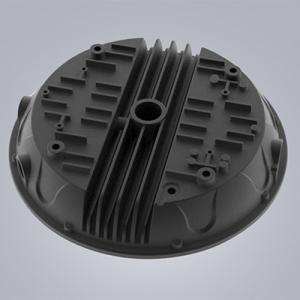

gear transmission

Materialaluminum

Zinc magnesium casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

Machiery accessories

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium milling parts