China PTJ machining shop specializes in kinds of Zinc Alloy die casting parts. We are with rich experiences in manufacturing Zinc, Aluminum, Magnesium Alloy tooling and mold design.

Our engineers have rich experiences and know-how with so many years practicing and producing in mold design and making field. Provide professional skill suggestion in mold design to our customer that can reduce risk and save more time in trial mold step, special in saving cost. Keeping high level zinc alloy die casting parts and producing effective is our mission.die casting parts a range of metal alloys, die casting has the following advantages:

1.Produces complex parts to net shape, reducing secondary machining

2.High-speed production compared to other manufacturing processes

3.Die cast parts are durable and have a long service life

4.Produces components with attractive, high-quality surface finishes

5.Produces a broad range of shapes and surface textures

6.Casts thinner walls than sand and permanent mold casting

7.Simplifies the assembly process by integrating fastening elements

8.Die cast parts are dimensionally stable, maintaining accurate tolerances

escription

Name & Description

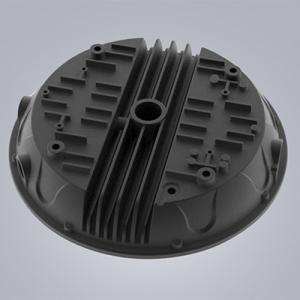

die casting parts

Materialaluminum

Zinc magnesium casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

Machiery accessories

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium milling parts