Custom manufacturer of die castings. Steel, stainless steel, alloy steel, aluminum, copper, magnesium, iron and lead materials used. Available in 2 cm L x 2 cm W x 2 cm H to 7 m L x 5 m W x 5 m H dimensions. Various casting methods include centrifugal, lost foam and sand casting. Castings are abrasion, acid and heat resistant. Assembly, engineering, finishing, inspection and other additional services offered. Prototype and low to high volume production can be done. Serves aerospace, agricultural, architecture and automotive industries. Blanket orders and CAD/CAM files accepted. Lean manufacturing capable. Rush and emergency services available. Meets ANSI, AS, ASME and ASTM, AWS, QS, SAE and TS standards.

Description

Name & Description

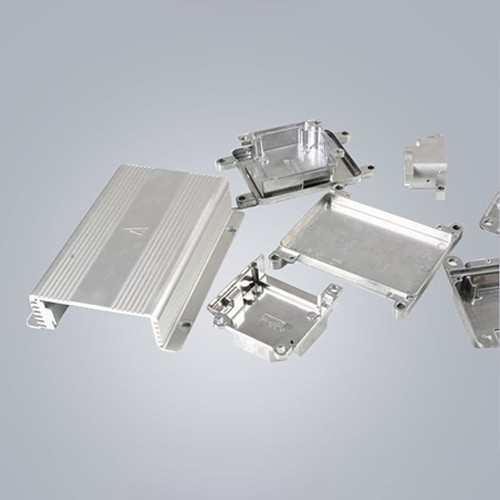

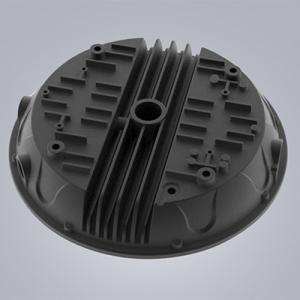

electronic parts disposal

Material

casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

electronic parts

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium die casting parts