Custom manufacturer of centrifugally cast, die, permanent mold, semi-permanent mold and spin castings. Alloy, aluminum bronze, brass, bronze, copper, copper nickel, phosphor bronze, silicon bronze and other materials used. Available in 0.5 to 18 in. height and 2.5 to 49.5 in. dia. Additional services such as assembly, inspection, collaborative engineering, machining, turning and specialized packaging also provided. Prototype, low to medium volume and small to large production runs. Serves the power transmission, marine, aircraft, automotive, oil, gas and wastewater treatment industries. SolidWorks® files accepted. Meets Mil-Spec and ANSI, ASME, ASTM, SAE and TS standards. RoHS compliant. Kanban delivery.

Description

Name & Description

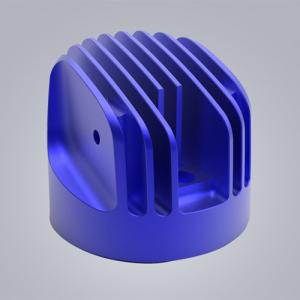

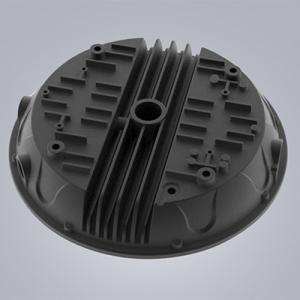

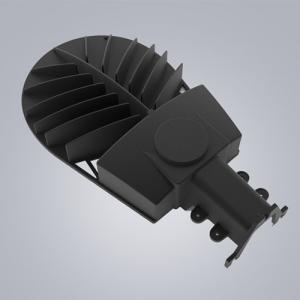

die casting electronic parts

Material

casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

electronic parts

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium die casting parts