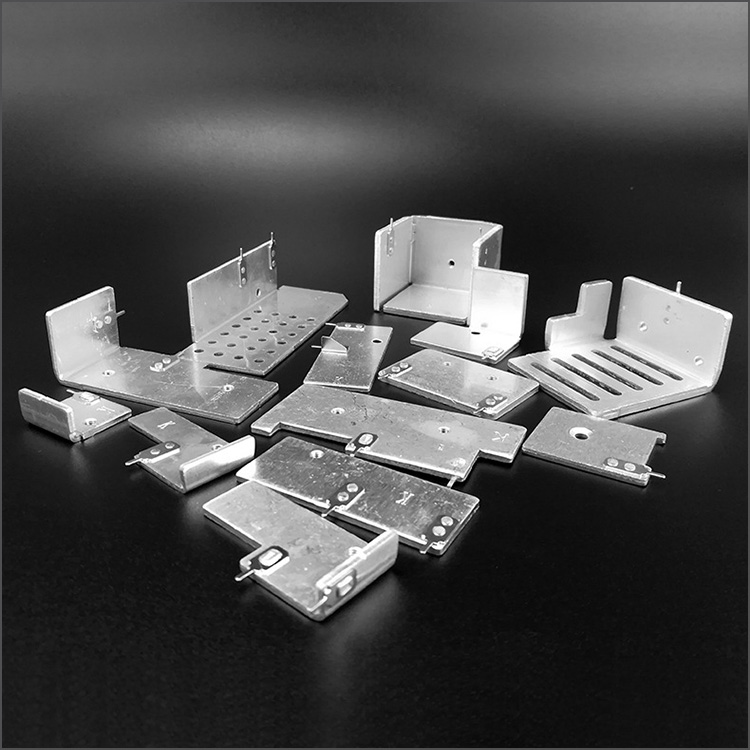

metal stamping services

Custom Metal Stamping

|

The stamping service relies on the press and the die to apply external force to the sheet, strip, pipe and profile to plastically deform or separate it, thereby obtaining the forming service of the workpiece (stamping part) of the desired shape and size. |

PTJ Shop's Capable of handling 0.04 mm to 4 mm material gage sizes and complex bending geometries at close tolerances. Available with in-house tool making. Utilizes automatic packing, raw material buffer, vision, and multi-coiler systems and stamping machines with 100 kN to 400 kN pressing force. Serves the automotive, electronics, consumer, entertainment, and telecommunication industries. Provides product consultation and development and water-based solution cleaning, vibratory finishing, and surface refinement services.

LED High Bay Light heatsink stamping mold case studies:

- 100W-300W heatsink stamping mould

- High power bulb heatsink stamping mould

- 100W-240W tunnel light module stamping mould

- 100W-500W flood light module stamping mould

- High Bay Accessories stamping mould

|

View Samples |

|

|

Services Range:

-

stamping parts

- stamping mould

- cnc machining

- Drilling

- Tapping

- Rolling

-

Forming

- Leveling

- Polishing

- Grinding

-

Consulting

Meets Material:

- Aluminum

- Cold Rolled Steel

- Hot Rolled Steel

- Stainless Steel

- Beryllium Copper

- Galvanized

-

Brass

Quality Control

PTJ Manufacturing precision metal stampings are produced from .001″ (.0254 mm) to .080″ (1.524 mm) thickness.Our 100W heatsink stamping sheet thickness is 0.060.

|

|

||

|

|

Turn to PTJ for Your Custom Sheet Metal Stamping Projects

PTJ produces millions of custom sheet metal stampings each year at our state-of-the-art 5,000 square-foot production facility. We invest over $0.5 million annually to upgrade our equipment to stay ahead of the demands of modern industry, and our employees are thoroughly trained in the latest precision metal stamping technology.

We produce only the highest quality custom metal stampings. Our workforce is dedicated and committed to quality through Quality Circle involvement. PTJ's quality management system is now certified to ISO9001:2015 standards.

PTJ

Manufacturing Shop utilizes various techniques to satisfy their worldwide

clients with services such as rapid CNC machining, rapid prototypes, rapid

sheet metal work and rapid die-casting among others.

Contact details

PTJ Manufacturing shop

Sifangyuan Industrial Park, Xinshapu

Huaide, Humen, Dongguan China 523000

Phone: +86-15118255600

Email: sales@pintejin.com or Click to Email Michelle

Web: https://www.ptjmachining.com