Custom manufacturer of aluminum die & zinc die castings. Specializing in high volume, custom-made or OEM products & sub-assemblies prepared to customer's design & specifications. Experienced procurement service in the Pacific Rim region, quality assurance, & development of new products. Products or sub-assemblies are made up of many materials & involve several manufacturing techniques. Secondary operations include precision machining, mechanical assembly, finishing, packaging, electrical or electronic & mechanical assembly at UL listed facilities, as well as heat treatment. Final steps include wet painting, powder coating, electrical plating or electric deposit, & finished products packaging. Engineers & inspectors conduct in-process quality control at manufacturing.

Description

Name & Description

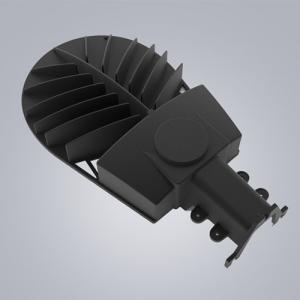

electronic parts and accessories

Material

casting alloy

Finish Treatment

oxidation

Tolerance

+/-0.02MM

Application

electronic parts

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton.

Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium die casting parts